How to Read and Clear Fault Codes on Jeep Vehicles

Jeep is a rugged and reliable companion, but like any other vehicle, it occasionally breaks down. When these glitches or malfunctions arise, your Jeep’s cluster may show warning lights such as ABS, SRS, transmission temperature, oil pressure, battery charging, differential, Tract control, check engine light, etc. These lights mean something: they are saved in your vehicle’s On-Board Diagnostic, where an OBD-II Scanner is used to interpret and ready the codes.

Most modern vehicles now include an OBD port, which can be utilized by a scanner that communicates to your vehicle. It is plugged in by an OBD-II scanner into the socket designed to help automotive technicians interpret faults and other issues that your Jeep may be experiencing or have recorded. All Jeeps have an OBD-II port; some common models include Wagoneer, Wrangler, Avenger, Compass, Commander, Renegade, and Gladiator. Although some older models do not have an OBD-II port, you can decipher DTCs through the flashing pattern of the Check Engine Light.

How to Read and Clear Jeep Codes with an OBD-II Scanner

Follow these steps to read the fault codes from Jeep vehicles.

- Gather the necessary tools: Equip yourself with a Professional-Grade OBD-II Scanner compatible with your Jeep. Check our scanner: Professional-Grade YOUCANIC Scanner.

- Access the OBD-II Port: This port is usually found under the dashboard, near the steering column; the OBD-II port is the gateway to your car’s diagnostic information. Turn the ignition key to the “ON” position without starting the engine to make a connection with the vehicle’s computer. If your Jeep has a START/STOP feature, press the button without pressing the brake pedal. Do not start the engine. If you are unsure of the OBD-II port of your vehicle, you can always check the Car Owner’s Manual.

- Turn on the ignition. Do not start the engine.

- Access the Diagnostic Menu: On the YOUCANIC scanner’s display, navigate to the “Diagnostic” or “Scan” menu. This menu allows you to access various diagnostic functions for your Jeep.

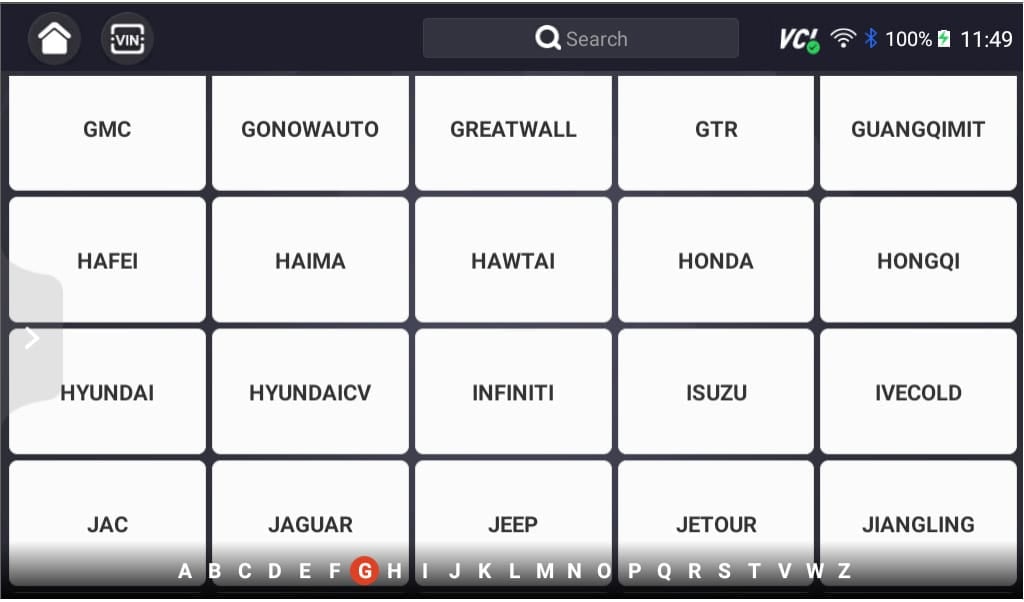

- Select ‘Jeep’ as the Vehicle Make: This ensures the scanner effectively communicates with the Jeep’s On-Board Diagnostic system and effectively scans the fault codes.

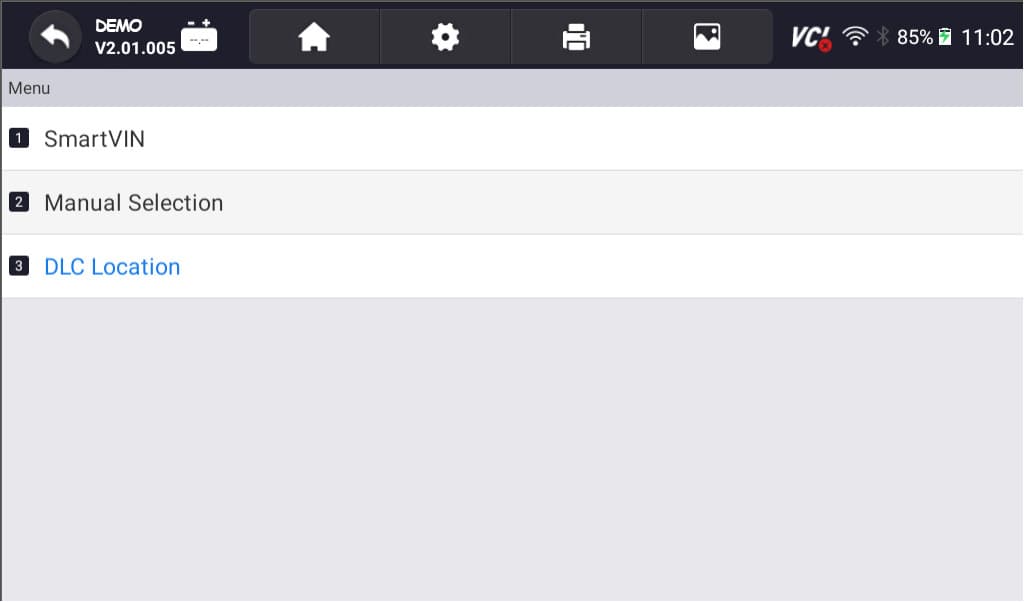

- Select option for model selection: The scanner has various options; you can choose SmartVIN to detect your vehicle automatically. However, you choose Manual Selection if SmartVIN does not work as intended.

- Select the Specific Model and Chassis: After selecting the vehicle make, scroll through the available models and select the correct one for your Jeep. Choose the corresponding chassis or body type to properly sync the scanner to your vehicle.

- Select Control Units: Once you have selected the model and chassis, the scanner will let you choose between “Quick Scan” or “Control Modules.” Control Modules display a list of control units or modules in your vehicle. Examples include the engine control module (ECM), transmission control module (TCM), and ABS control module. Choose the specific module you want to diagnose. Otherwise, you can also choose the “Quick Scan” to check everything.

- Interpret the Codes: Once the YOUCANIC scanner completes the code retrieval process, the displayed codes will provide information about specific issues detected by the control unit. Take note of these codes for further analysis and diagnosis. Each DTC consists of a letter and four numbers. The letter indicates the system affected, while the numbers describe the issue more specifically. Click here to learn more about fault codes.

- Erase Codes: After the problem has been repaired, return to the scanner’s menu and select the option to “Erase Codes” or “Clear Codes.” This action removes the stored fault codes from the control unit’s memory, indicating that the problem has been resolved. Please note that you may or may not erase a code when the issue is not fixed.

NOTE: These pictures are just the demo of our YOUCANIC Scanner. It may or may not be the same.

How to Read Jeep Fault Codes without a Scanner

This guide outlines retrieving OBD I and OBD II diagnostic trouble codes for various Jeep models, including YJ, TJ, XJ, ZJ, and early WJ.

Steps:

- Insert the ignition key.

- Within 5 seconds, turn the ignition On-Off-On-Off-On.

- Observe the 2-digit Diagnostic Trouble Code (DTC) indicated by the flashing Check Engine Light (MIL).

For example, DTC 24 is shown as 2 flashes, a short pause, and 4 more flashes. Multiple codes are separated by longer pauses.

DTC Explanations:

- 11 – No crank reference signal detected during cranking. Intermittent loss of camshaft or crankshaft position sensor.

- 12 – Positive battery input to PCM disconnected in last 50 key-on cycles.

- 13 – No change between engine MAP reading and barometric pressure at startup.

- 14 – MAP sensor voltage too high or low. Open 5-volt output to MAP sensor.

- 15 – No vehicle speed sensor signal during driving.

- 17 – Engine didn’t reach operating temperature quickly enough.

- 21 – Slow upstream oxygen sensor response. Issues in oxygen sensor heating elements (upstream/downstream). High or low oxygen sensor voltage after cold start.

- 22 – Engine coolant temperature sensor voltage issue.

- 23 – Intake air temperature sensor voltage issue.

- 24 – Throttle position sensor voltage issue. Inconsistency with MAP sensor.

- 25 – Issue in idle air control motor circuits. Idle speed not meeting target.

- 27 – Injector #1-6 control signal issues.

- 31 – A/C clutch relay circuit issue. Evaporative emission system flow problem.

- 33 – Issue in duty cycle purge solenoid circuit (A/C clutch relay circuit).

- 34 – Issue in Speed Control solenoid circuits. Low speed control switch input voltage.

- 37 – No torque converter clutch engagement. Issues in torque converter solenoid circuit or Park/Neutral switch (Automatic transmission only).

- 41 – Generator field control circuit issue.

- 42 – Auto shutdown relay circuit issue. Problems in ASD relay output circuit or fuel pump relay control circuit. Issues in circuit between PCM and fuel gauge sender.

- 43 – Inadequate primary circuit current peak. Misfires detected in cylinders.

- 44 – Battery temperature sensor voltage problem.

- 46 – High battery voltage during engine operation.

- 47 – Low battery voltage during engine operation or no change in generator output circuit.

- 51 – Lean air/fuel mixture indicated by correction factor.

- 52 – Rich air/fuel mixture indicated by correction factor.

- 53 – Internal PCM fault.

- 54 – No camshaft signal during engine cranking.

- 55 – End of fault code display on Check Engine lamp.

- 62 – PCM failed to update service reminder indicator.

- 63 – Failed EEPROM write attempt by PCM.

- 64 – Low catalyst efficiency (same as code 72).

- 65 – High power steering pressure at high speed (2.5L only).

- 72 – Low catalyst efficiency (same as code 64).

- 77 – Malfunction in power feed to speed control servo solenoids.

How to Clear Fault Codes

To clear the codes, disconnect and reconnect the battery for 5 minutes. This will clear some codes but not all. If the code is unclear, use the method above and an OBD-II Scanner to clear the codes.

On the 2018 and newer Jeep vehicles you will need to bypass the Security Gateway Moduel to be able to clear codes. Otherwise when you hit clear on the OBD-II scanner the fault codes will not clear.

Common Fault Codes

Here are 20 common fault codes for Jeep vehicles, along with their definitions and potential causes:

- P0300 – Random/Multiple Cylinder Misfire Detected: Indicates multiple cylinders are misfiring, possibly due to bad spark plugs, ignition coils, or a faulty fuel system.

- P0171 – System Too Lean (Bank 1): This code suggests that the air-fuel mixture is too lean in Bank 1, potentially caused by vacuum leaks, failing fuel injectors, or a defective oxygen sensor.

- P0420 – Catalyst System Efficiency Below Threshold (Bank 1): Points to a less efficient catalytic converter on Bank 1, potentially due to its deterioration or a faulty oxygen sensor.

- P0455 – Evaporative Emission Control System Leak Detected (Gross Leak): Indicates a significant leak in the EVAP system, possibly due to a loose fuel cap, damaged hoses, or a faulty EVAP canister.

- P0340 – Camshaft Position Sensor ‘A’ Circuit Malfunction (Bank 1 or Single Sensor): Suggests a problem in the camshaft position sensor circuit, potentially due to a faulty sensor or wiring issues.

- P0301 – Cylinder 1 Misfire Detected: Specific to a misfire in cylinder 1, often due to problems with spark plugs, ignition coils, or a clogged fuel injector.

- P0128 – Coolant Thermostat (Coolant Temperature Below Thermostat Regulating Temperature): Suggests a malfunctioning thermostat or a low coolant level.

- P0441 – Evaporative Emission Control System Incorrect Purge Flow: This indicates an issue with the EVAP system purge flow, potentially caused by a faulty purge valve or blockages in the system.

- P0014 – Exhaust Camshaft Position Timing – Over-Advanced (Bank 1): Indicates the exhaust camshaft timing is too advanced, potentially due to oil flow issues or a faulty camshaft position actuator.

- P0456 – Evaporative Emission System Leak Detected (Very Small Leak): Suggest a minor leak in the EVAP system, possibly due to a loose fuel cap or small hose cracks.

- P0138 – O2 Sensor Circuit High Voltage (Bank 1 Sensor 2): Indicates the oxygen sensor is producing a higher voltage than normal, potentially due to a faulty sensor or exhaust leak.

- P0404 – Exhaust Gas Recirculation Circuit Range/Performance: Suggests a problem with the EGR system, possibly due to a faulty EGR valve or clogged passages.

- P0442 – Evaporative Emission Control System Leak Detected (Small Leak): Indicates a small leak in the EVAP system, possibly due to a loose fuel cap, cracked hoses, or a faulty EVAP canister.

- P0562 – System Voltage Low: Suggests the vehicle’s electrical system voltage is low, possibly due to a failing alternator or poor battery condition.

- P0700 – Transmission Control System Malfunction: Indicates a problem within the transmission control system, requiring further diagnosis.

- P0135 – O2 Sensor Heater Circuit Malfunction (Bank 1 Sensor 1): Suggests a malfunction in the oxygen sensor heater circuit, potentially due to a faulty sensor or wiring issue.

- P0302 – Cylinder 2 Misfire Detected: Specific to a misfire in cylinder 2, often due to problems with spark plugs, ignition coils, or a clogged fuel injector.

- P0335 – Crankshaft Position Sensor ‘A’ Circuit Malfunction: This indicates an issue with the crankshaft position sensor circuit, potentially caused by a faulty sensor or wiring issues.

- P0121 – Throttle/Pedal Position Sensor ‘A’ Circuit Range/Performance Problem: Suggest a problem with the throttle position sensor, potentially due to a faulty sensor or wiring issues.

- P0325 – Knock Sensor 1 Circuit Malfunction (Bank 1 or Single Sensor): Indicates a malfunction in the knock sensor circuit, potentially due to faulty sensor or wiring problems.

As with any vehicle, these fault codes are just starting points for diagnosis. Conducting a thorough check to identify and resolve issues accurately is important.

DIY as an Enthusiast or consult a mechanic?

Whether to tackle DTCs yourself or seek professional assistance depends on your mechanical aptitude and the issue’s complexity. If you’re a seasoned DIY enthusiast with a well-stocked toolbox, you might be able to handle minor issues. However, for more intricate problems, it’s wise to entrust your Jeep to the expertise of authorized Jeep technicians.

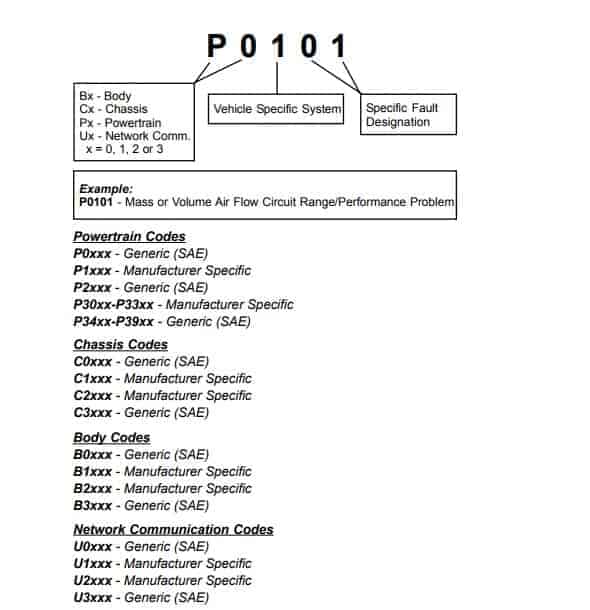

Decoding the Enigma of DTCs

DTCs are standardized codes that follow a specific format, providing valuable insights into the nature of the problem. The first character indicates the type of system (P for powertrain, B for body, C for chassis, and U for network comm.), followed by four digits. The first digit identifies the system, the second digit denotes the subsystem, and the last two digits pinpoint the specific fault.

For instance, a DTC starting with P01 would indicate a powertrain issue related to fuel or air metering. Further, a code like P0171 would point to a lean air-fuel mixture.

Why Should I Scan My Vehicle?

Regular scanning offers several benefits:

- Early Detection of Issues: DTCs can alert you to potential problems before they cause noticeable symptoms, allowing for timely intervention.

- Improved Fuel Efficiency: Addressing underlying issues can enhance fuel economy, saving you money at the pump.

- Extends the Vehicle Lifespan: Promptly addressing faults can prevent further damage and prolong your Jeep’s lifespan.

Regular scanning is like visiting your doctor annually as a preventive checkup for your Jeep. Your Jeep deserves regular attention to keep it running smoothly and safely.

Why can’t I clear my Jeep’s error codes?

Once you’ve identified the DTCs, you may be tempted to clear them, hoping to continue driving your Jeep, and the problem magically disappears. Clearing the codes can temporarily remove the “Check Engine” light, butit doesn’t address the underlying issue. It will always come back. Here are also some lists of why you cannot clear the codes of your Jeep:

- Use a Professional-Grade Scanner: Ditch the generic scanner and upgrade to a professional-grade like YOUCANIC. Generic scanners are like trying to open a Ferrari with a Ford key – it won’t work! YOUCANIC, on the other hand, is like the master key to your Jeep’s diagnostics, unlocking hidden diagnostic powers and letting you clear codes that would otherwise remain stubborn and hidden.

- Underlying Issues: Before clearing fault codes, remember to address the underlying issue that triggered them in the first place. Clearing codes is like patching a leaky pipe without fixing the cracked valve – it’s just a temporary fix. The ‘check engine’ light will surely come back and haunt you.

- Continuous Fault Monitoring: Like the SRS system, certain fault codes may be cleared by disconnecting the battery (like a reset). However, they will reappear even after clearing until the root cause is resolved. This is a persistent reminder to fix the problem, not just mask it.

- Proper Clearing Procedure: Following the correct steps outlined in your diagnostic scanner’s user manual is essential to clear fault codes effectively. If unsure about the clearing procedure, consult a professional for guidance specific to your scanner and Jeep model.

Check our YOUCANIC Scanner:

What Happens When I Ignore Fault Codes?

Ignoring DTCs can lead to a cascade of issues.

- Performance: Over time, unaddressed faults can lead to decreased performance, reduced fuel efficiency, and increased emissions.

- Safety Hazard: Ignored DTCs can pose safety risks, particularly related to critical systems like brakes or airbags.

- Costly Repairs: Putting off repairs can result in more extensive damage, such as damage to your transmission, leading to higher repair costs in the long run.

Frequently Asked Questions:

How often should I scan my Jeep?

Regular scanning is advisable, especially if you notice any changes in your vehicle’s performance or behavior.

Are there any free DTC scanning tools?

Several free OBD-II scanning apps are available for smartphones. However, their capabilities are not advisable. It is always better to use professional-grade scanners.

References:

- What Is an OBD2 Scanner and How Does It Work?

What Is an OBD2 Scanner and How Does It Work? | The Drive - DTC Fault Codes

DTC Fault Codes – YOUCANIC - What Does the Check Engine Light Look Like, and What Does It Mean?

What Does the Check Engine Light Look Like, and Really Mean? – Consumer Reports - Current / Stored / Active / Past / History Fault Codes Explained

Current / Stored / Active / Past / History Fault Codes Explained – YOUCANIC - A Guide to Understanding DTC Codes

A Guide to Understanding DTC Codes (samsara.com)